Our Products

What we produce

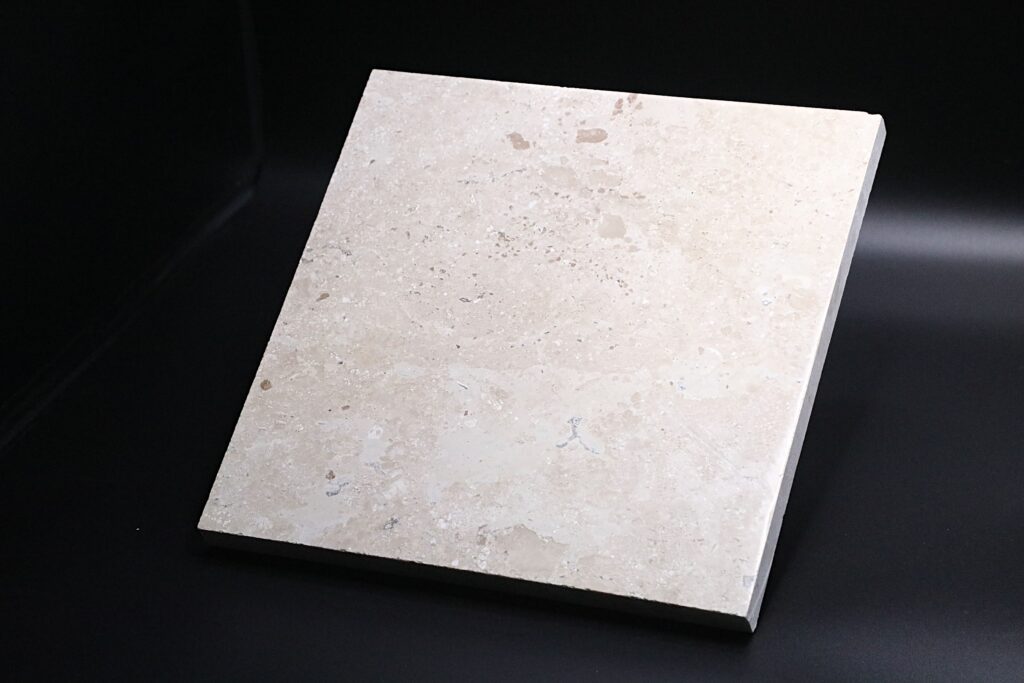

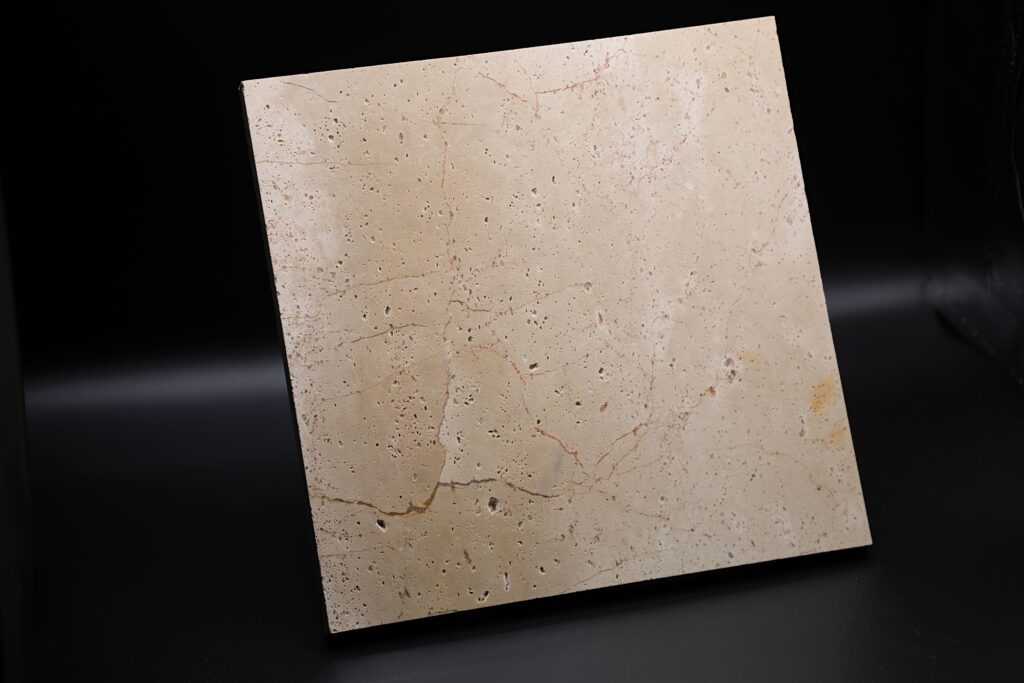

Travertine Marble

Travertine marble is a sedimentary stone classified as a form of limestone with naturally occurring holes and troughs throughout the surface which result in porousness.

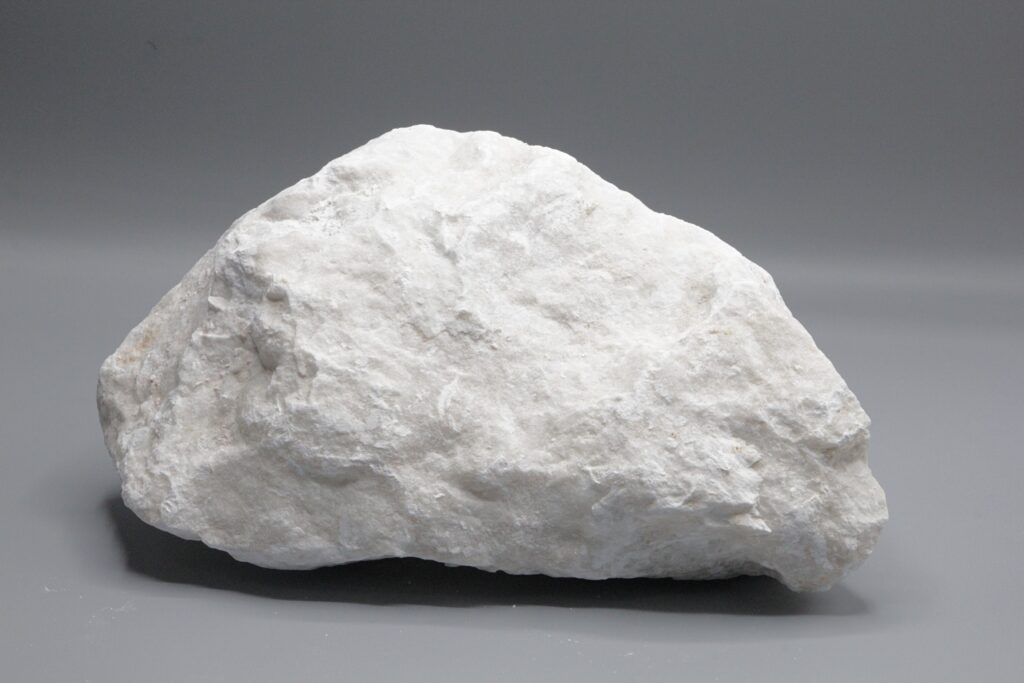

Calcium Carbonate

The company has plans to have a calcium carbonate production line to produce different qualities for the local and international market.

Salt

Salt production is one of the oldest chemical practices performed by man. Although salt is produced naturally when seawater evaporates.